Advanced Fasteners and Machining Techniques for Custom-made Manufacturing

Advanced Fasteners and Machining Techniques for Custom-made Manufacturing

Blog Article

Grasping the Art of Bolts and Machining: Advancements and Finest Practices

In the world of industrial manufacturing and engineering, the mastery of fasteners and machining is a keystone of making certain architectural honesty, functionality, and durability in numerous applications. As technology breakthroughs and demands for performance and precision rise, staying abreast of the most up to date developments and ideal practices in attachment and machining becomes crucial. From the advancement of securing innovations to the complexities of picking the most suitable products, the landscape of modern-day production is continuously progressing. Join us as we check out the latest advancements and look into the nuanced globe of grasping bolts and machining, uncovering vital understandings and strategies that can raise your strategy to engineering options.

Evolution of Fastening Technologies

Throughout the industrial transformation and into the modern period, the advancement of attaching innovations has been marked by continual developments in performance and integrity. Bolts, such as rivets, screws, and bolts, play an essential role in various markets, consisting of automobile, aerospace, construction, and electronics. The demand for stronger, much more long lasting, and easier-to-install attachment services has actually driven technology in the field.

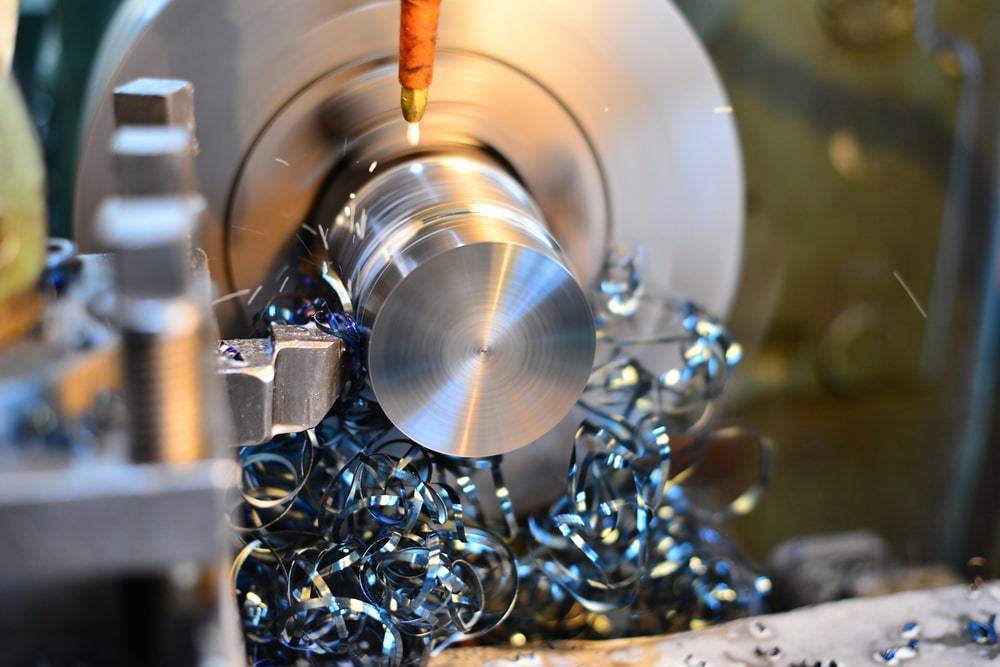

One considerable growth has been the change in the direction of precision machining strategies to create bolts with greater tolerances and premium performance. This change has actually made it possible for manufacturers to produce fasteners that meet strict quality criteria and deal increased resistance to corrosion and fatigue.

Furthermore, the introduction of innovative products, such as titanium alloys and composites, has actually reinvented the capabilities of bolts. Fasteners and Machining. These products supply outstanding strength-to-weight ratios, making them ideal for applications where reducing weight is vital without endangering architectural integrity

Improvements in Machining Methods

In the world of commercial production, the continuous evolution of machining approaches has actually paved the method for extraordinary precision and efficiency in the manufacturing of fasteners. One of the considerable improvements in machining methods is the application of Computer system Numerical Control (CNC) technology. CNC equipments use unrivaled precision and repeatability by permitting for automated control of machining tools. This specific control enables manufacturers to produce complicated and complex fastener designs with simplicity.

Additionally, the adoption of multi-axis machining facilities has allowed synchronised cutting operations from various angles, additionally improving efficiency and reducing manufacturing times. By utilizing these advanced machining methods, producers can satisfy the raising demand for top quality bolts while keeping cost-effectiveness in their operations.

Picking the Right Fastener Materials

Selecting the appropriate product for fasteners is a vital choice that dramatically influences the efficiency and durability of the assembled components. When picking the appropriate fastener material, numerous variables must be thought about to ensure the sturdiness and dependability of the end product. The material picked must work with the ecological problems the bolts will certainly be exposed to, such as temperature variations, wetness degrees, and harsh elements.

Common products made use of for fasteners consist of stainless-steel, carbon steel, titanium, and light weight aluminum, each offering special homes that fit various applications. Stainless-steel, for instance, is understood for its rust resistance, making it excellent for outside or marine environments. Carbon steel is an affordable alternative ideal for numerous general-purpose applications. Light weight aluminum is lightweight and typically used in sectors where weight is a critical element. Titanium, on the other hand, is corrosion-resistant and exceptionally solid, making it appropriate for high-performance applications.

Enhancing Precision in Machining

Achieving optimal precision in machining is important for ensuring the quality and performance of machined parts. To improve accuracy in machining, makers use a selection of innovative methods and modern technologies.

In enhancement to CNC machining, the use of sophisticated cutting tools and device holders can likewise substantially enhance accuracy. By focusing on precision in machining, producers can achieve premium product quality, tighter tolerances, and boosted total efficiency of machined components.

Ideal Practices for Bolt Installation

Precision in machining plays a critical function in ensuring the reliability and long life of bolt installments. When it pertains to finest methods for fastener installation, one key element is the proper option of fasteners based on the certain application demands. Using the proper kind, dimension, and product of fastener is crucial to ensure optimal performance and longevity. Fasteners and Machining. Furthermore, it is vital to adhere to supplier guidelines and suggested torque worths throughout the installation procedure to avoid over-tightening or under-tightening, which can cause early fastener failure.

Moreover, making certain Related Site that the bolt strings are tidy and cost-free of debris prior to setup is important to achieving a safe and efficient link. By sticking to these best methods, makers can maximize the stability and efficiency of their bolt installations.

Verdict

To conclude, the evolution of securing modern technologies and improvements in machining approaches have actually significantly enhanced the performance and efficiency of fastener installation procedures. By picking the ideal fastener materials and improving accuracy in machining, producers can attain optimal cause their operations. Adhering to ideal practices for fastener setup is vital in guaranteeing the resilience and integrity of settings up. On the whole, mastering the art of fasteners and machining entails continuous technology and adherence to ideal techniques.

In the world of industrial manufacturing, the continuous advancement of machining methods has paved the means for extraordinary precision and effectiveness in the production of fasteners.Accuracy in machining plays an essential role in making sure the reliability and durability of fastener setups. When it comes to ideal techniques for bolt installment, one essential facet is the correct choice of fasteners based on the specific application demands. By picking the best bolt products and improving precision in machining, manufacturers can achieve optimal outcomes in their procedures. In general, mastering the art of bolts and machining use this link includes continuous technology and site link adherence to finest techniques.

Report this page